SUMMARY – Solar Powered Wastewater Treatment

Self-powered on-site processing of wastewater provides a unique capability for distributed wastewater mangement. This holds the potential to reduce haulage costs and eliminates resources typically required to collect and haul wastewater from remote locations.

The REGEN 20 solar powered wastewater treatment solution integrates technological advances that significantly reduce the cost and energetic input of the wastewater treatment process. Integrating renewable energy and advances in wastewater treatment with improvements in remote automation significantly reduces the inefficiencies in current wastewater treatment processes.

At IWT we offer this validated solution for remote work camps, humanitarian and military applications.

The Canadian Military completed testing with Colonel Nicolas Pilon stating:

“The system was fully powered by solar energy, typically drawing only 2.5 kWh/m3. Overall, the system required only minimal operation and maintenace and exhibited great potential”

Introduction

The REGEN 20 is a world first, solar powered wastewater treatment system for decentralized wastewater treatment applications. This modular treatment technology leverages advances in Fixed Film wastewater treatment and biosensors with a renewable power management system to provide stand-alone, self-powered wastewater treatment. This autonomous treatment system can be deployed to remote population clusters and provide a packaged solution for on-site wastewater treatment.

Island Water Technologies was contracted by the Canadian Military to provide a modular wastewater treatment unit that uses renewable power and energy storage and would be suitable for remote camps and humanitarian operations. The unit was tested over an 8-week period by the Canadian Military. The REGEN 20 was installed on March 25th by the Canadian Military. Under the instructions of IWT the unit was supplied raw municipal sewage from a local municipal lift station. This document provides a description of the REGEN 20 technology and 3rd party testing provided by the Canadian Military.

Solar powered wastewater treatment solution

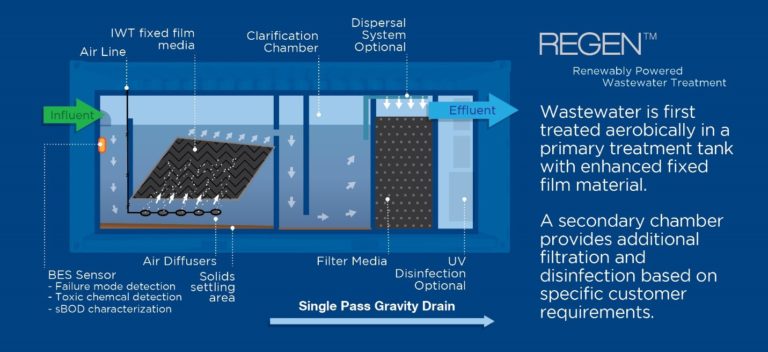

REGEN Process Description – Novel “single-pass” wastewater treatment process design

The system is designed with reduced process complexity, and to provide additional functionality, enabling a reduction in overall tankage. This was accomplished by re-evaluating each step and achieving more removal / treatment per tank. The result is a streamlined single-pass wastewater treatment design. Complexity, (i.e. moving parts) is removed where possible to keep operator maintenance and energy costs to a minimum.

- Improved fixed-film polymer materials:

As part of identifying enabling technologies we have analyzed all current solutions for wastewater treatment and have identified fixed film solutions as offering the best option for reducing the energetic input (kWh/m3) to the system. IWT carried out 2 years of R&D focused on identifying polymer materials that are best suited to biofilm formation. Our studies have shown an increase in treatment rates of up to 50% when compared to control samples, as shown in Figure 3. Improved polymer materials have been identified or developed that can allow for the enhanced removal of BOD, TSS and TKN. As shown in Figure 4, the fixed film was developed to have both a polished and treated side. The material alterations were tested by Carleton University. This unique setup allows for improved solids settling on the polished side, while providing additional surface area for bacteria growth on the treated side. When the media is used in the reactor, the fixed film is angled along the flow-path in the reactor. The fixed film serves a dual purpose of lamella plate type clarification at the same time as providing a surface area for biological growth. This structure essentially creates “tubes” which the wastewater is forced through. The tube “top” is treated specifically to provide additional surface area for biological growth. The tube “bottom” is smooth to allow solids the chance to accumulate and slide down the media and settle out of solution.

REGEN Process

- Biological Filter

IWT has developed a biological filter for the REGEN product. This component provides the dual purpose of solids / COD filtration as well as a large surface area for bio-growth and some adsorption processes. Depending on the treatment requirements of the REGEN, this granular material has the option of being just a physical filter unit, or with the addition of aeration, it can provide additional bio-active filtration and Nitrogen removal. The large surface area provides an excellent medium for biological growth and for solids removal. GAC filtration allows the unit to meet treatment standards rapidly during start-up, and helps produce a higher quality effluent. The biomass is attached directly to the fixed film surface. This results in a lower concentration of suspended solids in the bulk liquid. As a consequence, the advanced fixed film system produces approximately 50% less sludge at the end of the treatment process when compared to conventional activated sludge processes.

- BACKUP POWER SYSTEM

The power skid, otherwise known as the backup power system, includes all the control and automation to ensure that the overall AC dependent system is powered correctly and on a consistent basis. This involves the control, monitoring and selection of the following sources:

- Solar Photovoltaic (PV) Paneling;

- Battery Based Energy Storage System;

- 13 kW 120/240VAC Auxiliary Generator; and

- 120/240VAC Grid power.

Source selection is carried out via the combined inverter battery charger major device and is set to consider a supply hierarchy which prioritizes solar power and energy storage over diesel generation and grid power. Bypass functionality is also built into the design with a safety interlock system. During the testing period the REGEN 20 was powered fully by solar energy and energy storage system.

INSTALLATION AND OPERATION

The REGEN 20 requires minimal site preparation and footprint. This system is designed with minimal complexity resulting in reduced operation and maintenance. The self-powered capability allows for the treatment system to be located independent of a grid electrical connection.

REGEN system installation

Installation of the REGEN solar powered wastewater treatment system was completed over a 3-day period by the Canadian Military under the supervision of IWT. This included moving the unit to site, deployment of solar panels, and installation influent pump and piping. The Canadian Military monitored and sampled influent and effluent daily over an 8-week period. The operation of the unit was mainly controlled by the REGEN 20’s PLC unit. The Canadian military was required to increase the flow to the unit at intervals, as well as monitor for any mechanical failures. IWT was able to monitor the functionality of the unit remotely through the 3g network in case of mechanical failures or issues.

TESTING PROCEDURE

All maintenance and tests were conducted in accordance with the standards and guidelines for waste water treatment “Hach ISO 9001 Certified Water Analysis Handbook 3rd Edition”. Key metrics that were measure were influent and effluent COD, TSS and system capacity (gallons per minute). Testing was carried out to align with standard NSF 40 test protocols with wastewater samples taken daily (5 days a week).

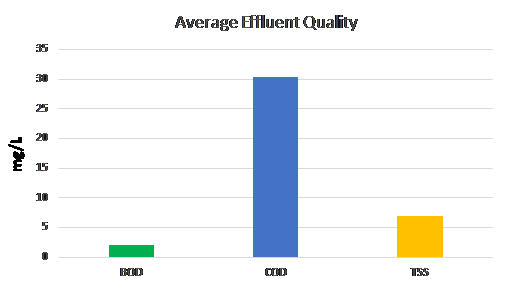

Effluent samples were taken from an effluent port after the last stage of treatment and tested for COD and TSS daily by the Canadian Military. BOD data is currently not available, but will be provided by the military at a later date.

RESULTS

The results of testing show a high percent removal for both COD and TSS. The average mg/L of COD and TSS are 29 and 6 respectively. The unit was powered fully by solar energy and solar energy storage system over the testing period. The typical energy draw of the unit was 2.5 kWh/m3.

Test data

CONCLUSION

The REGEN 20 was able to treat municipal wastewater to a high standard while powered fully by solar energy. Over the 8-weeks of testing the unit treat to an average flow rate suitable for 75 persons or greater than 20 m3-day or wastewater.

The Canadian military onsite staff was pleased functionality in solar powered wastewater treatment, with the ease of use and lack of operational requirements.